3D SERVICES

We offer a comprehensive range of 3D services for design, modeling, scanning, and printing. We implement customer-centric and flexible product development processes, from ideation to 3D printing of prototypes or small production series, as needed. We have a versatile selection of equipment and materials, along with a 3K factory environmental testing laboratory, enabling extensive testing and research related to 3D printing. In addition to our printing services, we also provide tailored 3D-related training.

We also conduct material research related to 3D printing, utilizing the 3K factory testing equipment. For example, in material investigations, we seek the most suitable materials for various product applications. We have substantial experience in testing properties such as thermal conductivity, ingress protection, and radio signal permeability for various 3D printing materials.

The 3D printing development environment built at the 3K factory enables the design and production of innovative structural solutions.

HARDWARE

We have a versatile range of equipment for 3D printing and scanning. In addition to our in-house hardware, we have an extensive network of subcontractors through which we can subcontract, for example, metal and large-scale prints.

CASES

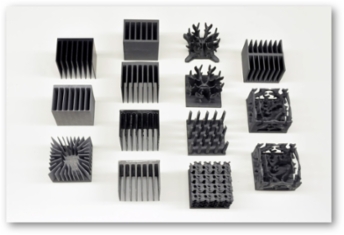

Enhancing Electronics Cooling through 3D Printing

The Electronics 3K Factory explored ways to improve cooling and replace the use of metals in various electronic cooling solutions. 3D printing enables even very complex structures as a manufacturing method, even bringing optimal, biomimetic shapes to cooling structures...

Soldering Jig

At the Electronics 3K Factory, component boards are produced, and as a post-assembly process, 9 connectors are soldered in a row. For the successful assembly and operation of the final component board housing, it is important that the connectors are precisely positioned. To ensure this and expedite the soldering process, a decision was made to 3D model and produce a two-part soldering jig using 3D printing...

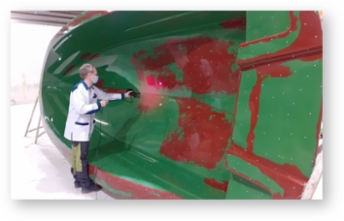

Boat Scanning and Reverse Engineering

Esmarin Composites was starting the production of composite parts for a new boat model. There was a mock-up of the inner bottom of the boat's hull, but no CAD model was available. A CAD model is necessary when planning a production chain, for example to optimize the use of materials. Therefore, the boat's hull was decided to be 3D scanned for reverse engineering the CAD model...

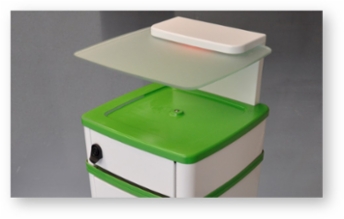

Assembly Base for a Disinfection Device

Mac Ltd manufactures hand sanitizer dispensers for large crowds of people. Mac Sanitize devices are used e.g. in shopping centers and transport stations. With increasing demand for these devices, there arose a need to improve their production. One of the development targets has been speeding up and simplifying the manufacturing of the sub-assembly formed by the device's internal electronics and electromechanics...

CONTACT US

mikko.t.nykanen@xamk.fi

050-5306751

EETU HUTTUNEN

RDI Specialist

050-5746655